Why Do Energy Storage Projects Always Go Over Budget? The Engineering Root Causes

From the perspective of an Imax power engineer, “budget creep” in energy storage isn’t usually caused by the price of the batteries themselves. In fact, battery prices are the most transparent part of the quote.

The reality is that 90% of budget overruns occur in the “Grey Zones”—the integration gaps, site-specific variables, and hidden engineering requirements that aren’t visible on a basic spec sheet. If you treat an energy storage product as a simple “black box” purchase, you are almost guaranteed to exceed your initial budget.

1. The “Hidden” Balance of System (BOS) Costs

Most first-time buyers focus on the $/kWh of the battery. However, the battery cells only represent about 50–60% of the total project cost.

-

The Trap: Underestimating the costs of the PCS, fire suppression systems, and thermal management units.

-

The Engineering Reality: At Imax power, we often see projects stalled because the customer didn’t account for the transformer upgrades or the switchgear required to connect the power product to the high-voltage grid. These “ancillary” components can easily add 20% to the total expenditure.

2. Integration and Communication Friction

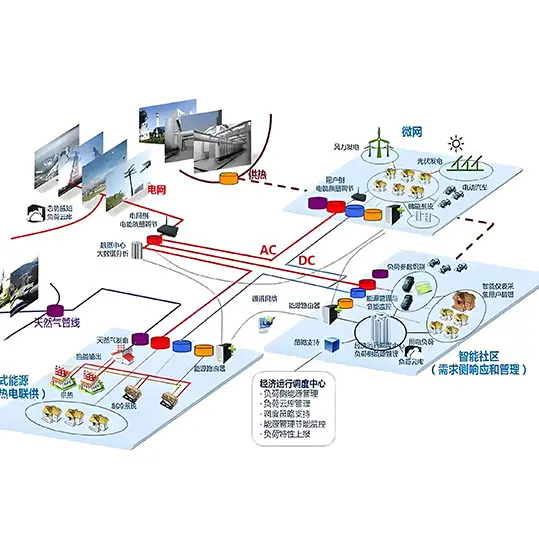

This is where the most “invisible” money is lost. An energy storage product must communicate perfectly with the local grid, the building’s EMS, and the battery’s internal BMS.

-

The Problem: If you buy a battery from Brand A, a PCS from Brand B, and software from Brand C, the field engineers will spend weeks (and thousands of dollars) trying to get the protocols to “handshake” correctly.

-

The Imax power Logic: This is why we advocate for integrated solutions. When the hardware and software are designed to work together from day one, you eliminate the “on-site debugging” fees that often plague fragmented projects.

3. Thermal Management and Site Environment

Engineers know that “Ambient Temperature” is a lie. A power product sitting in the sun in an industrial park will experience internal temperatures $20^\circ\text{C}$ higher than the outside air.

-

The Budget Killer: If the initial solution uses a cheap air-cooling system in a high-heat environment, the system will trigger safety derating.

-

The Result: The client has to spend more money on auxiliary cooling retrofits or face a 40% reduction in revenue-generating capacity. At Imax power, we insist on rigorous site-specific thermal modeling before the contract is signed to avoid these “emergency” upgrades.

4. Regulatory and Safety Compliance Creep

Energy storage safety standards (like UL9540A or NFPA 855) are evolving rapidly.

-

The Root Issue: A project quoted last year might not be legal to install this year without additional blast panels, specialized fire-extinguishing agents, or specific spacing between containers.

-

Our Approach: Imax power stays ahead of the curve. We build our energy storage products to the highest international safety standards, so you don’t get hit with a “Compliance Change Order” halfway through the installation.

Summary: How to Protect Your Budget

| Source of Overrun | How to Avoid It |

| BOS Costs | Demand a “Turnkey” quote that includes switchgear and transformers. |

| Integration Fees | Choose a vertically integrated solution from one provider. |

| Thermal Issues | Insist on liquid-cooled power products for C&I applications. |

| Safety Compliance | Ensure the hardware is pre-certified for the latest local regulations. |

Ultimately, a project stays on budget when the engineering is done upfront, not in the field. At Imax power, we believe that the most expensive solution is the one that was quoted too low to be realistic. We provide transparent, engineering-led solutions designed to get your project online without financial surprises.