What is a Power Conversion System (PCS)? Understanding the Core of Modern Energy Storage

In the architectural hierarchy of an Energy Storage System (ESS), if the battery bank is the “fuel tank” storing raw energy, then the Power Conversion System (PCS) acts as the “engine” and “transmission.”

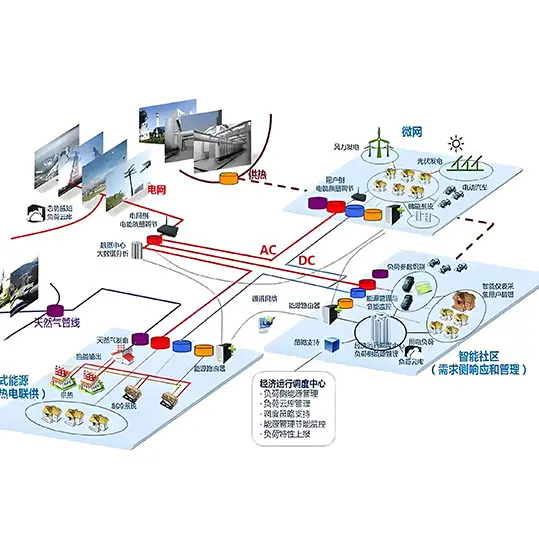

At its simplest, a PCS is a high-performance bidirectional power converter. It manages the transition of electricity between the DC (Direct Current) stored in batteries and the AC (Alternating Current) used by the utility grid or local loads. Without a reliable PCS, stored energy remains static and unusable for real-world applications.

The Engineering Logic: What Does a PCS Actually Do?

From the perspective of an Imax power engineer, a PCS is far more than a simple inverter. It executes four mission-critical functions within any professional power product:

-

Bidirectional AC/DC Conversion

In charging mode, the PCS acts as a rectifier to convert grid AC into DC for the battery. In discharge mode, it functions as an inverter. The conversion efficiency directly impacts the Levelized Cost of Storage (LCOS).

-

Precise Energy Flow Management

The PCS receives instructions from the Battery Management System (BMS) and the local controller. It regulates power output with millisecond precision to ensure batteries operate within safe voltage and current windows.

-

Grid Support and Seamless Switching

High-end solutions require the PCS to handle both Grid-tied and Off-grid modes. During a grid failure, the PCS must transition to “island mode” in less than 20ms to prevent power interruptions for critical loads.

-

Power Quality Optimization

By managing reactive power compensation and harmonic suppression, the PCS stabilizes the local grid environment. This ensures that the energy storage product contributes to a cleaner electrical ecosystem.

Why is the PCS Considered the “Brain” of the System?

In the field of solutions integration, the PCS is often the deciding factor in project success. Here is why it is so critical:

1. System Response Speed

Modern microgrids have zero tolerance for frequency fluctuations. When a heavy load starts, the PCS control algorithm must react within 10–50 milliseconds. At Imax power, we prioritize algorithm convergence speed to prevent protective shutdowns during transient events.

2. Battery Longevity and Health

While the BMS monitors the cells, the PCS actually executes the current delivery. High current ripple or voltage spikes from a low-quality PCS can cause internal battery heating. This leads to accelerated degradation of the active chemical materials.

3. Integration Complexity

A sophisticated power product requires seamless communication between the EMS, BMS, and PCS. The compatibility of communication protocols determines the commissioning time and long-term maintenance costs of the site.

Common Industry Myths: Is Higher Power Always Better?

When selecting an energy storage product, engineers must look beyond the spec sheet. We often see these common misconceptions:

-

Myth 1: Focusing only on Nominal Power.

Many units perform well at 25°C but derate significantly at 45°C inside a container. A robust solution must be evaluated based on its thermal management and high-temperature performance.

-

Myth 2: Ignoring “The Last 0.5%” Efficiency.

The difference between 98% and 98.5% efficiency may seem small. However, over a 10-year lifecycle, that 0.5% loss translates into thousands of dollars in wasted energy.

-

Myth 3: Treating PCS as a Standard Solar Inverter.

Solar inverters are unidirectional. A PCS must handle bidirectional flow and complex battery chemistry requirements, which demands much more sophisticated IGBT control strategies.

System-Level Thinking at Imax power

As Imax power engineers, we design every power product with a “Reliability-First” philosophy.

Our energy storage product lineup is built on three pillars of technical excellence:

| Dimension | Imax power Engineering Practice | Client Benefit |

| Topology | Advanced three-level inverter technology. | Lower harmonic distortion and higher battery safety. |

| Thermal Control | Independent air duct design with smart fan speed. | Guaranteed full-power operation in harsh environments. |

| Compatibility | Pre-configured protocols for major BMS brands. | Faster on-site commissioning and “Plug & Play” capability. |

We understand that every solution represents a commitment to energy security. Therefore, Imax power focuses on the dynamic response and long-term stability of our conversion hardware.