Why Natural Gas Recycling Station Power Systems Require “Exclusive Bodyguards”

Natural gas recycling stations are no ordinary industrial facilities. The equipment here operates under high pressure and heavy loads. If core equipment like compressors and capacitors loses power or malfunctions, it not only halts production but may also trigger serious safety incidents. In the Middle East’s unique power grid environment, where power demand and voltage standards differ from those in China, power protection systems face higher demands: they must accurately identify faults and adapt to localized power system rules.

The natural gas recycling station power distribution project undertaken by Chengdu Chijun Co., Ltd. is located in the Middle East. It adopts a two-infeed line, lead-acid dual-power supply system. The medium-voltage switch station is equipped with KYN28-12 switch cabinets, covering 1 bus tie PT cabinet, 6 compressor outlet cabinets, 1 capacitor outlet cabinet, and spare cabinets, among other core equipment. The system design must meet multiple protection requirements for current, voltage, and grounding faults, while supporting on-site control and modular maintenance.

Tailor-Made “Protection Team”: Different Equipment with Dedicated “Bodyguards”

Just as different positions require security personnel with varied skills, the circuits, motors, and capacitors in the power distribution system also need “exclusive bodyguards.” Ankeri’s AM series microcomputer protection devices form a “protection team,” with 11 devices each fulfilling their duties to precisely cover the entire power distribution system:

- Incoming Feeder Cabinet: The AM6-L line protection device integrates functions such as instantaneous/time-overcurrent, overvoltage, and phase-sequence protection. It also features circuit breaker failure protection and automatic reclosing monitoring. If abnormal current or voltage occurs, it triggers protection instantly to prevent line overload and burning.

- Electric Motor Cabinet: The AM6-M motor protection device adds reverse-phase current relays, overload protection, and ground fault protection, ensuring the safe operation of key motors like compressors.

- Capacitor Cabinet: The AM6-C capacitor protection device focuses on overcurrent, overvoltage, and ground fault monitoring, preventing capacitor damage due to wave or overload.

- PT Cabinet and Network: Configured with AM6-UB voltage monitoring devices and AM6-B/AM5-DB self-input devices, it achieves rapid switching between power sources with abnormal voltage warnings.

These devices are not “one-size-fits-all” standardized products. Tailored to local power supply demands in the Middle East, they customize display functions to ease operations for on-site technicians. Protection parameters also adjust based on grid characteristics, ensuring precision in complex environments.

“Black Technology” in Details: How to Achieve “Zero Misjudgment, Millisecond Response”

In high-voltage power distribution systems, “misjudgment” may cause unnecessary shutdowns, while “slow response” can expand fault ranges. The AM series operates stably in Middle East projects, relying on these “black technologies”:

- Independent Protection Nodes: Overcurrent, overvoltage, and ground protection functions have independent relay output nodes, supporting fault status display. This allows real-time monitoring of multiple operations.

- Anti-Interference Design: Early in the project, voltage protection occasionally misoperated due to interference from tap changers. Through wave recording, data analysis, and optimizing protection trigger points, interference risks were eliminated.

- Intelligent Self-Investment Logic: For lead-acid systems, “inspection period” and “non-inspection period” dual-mode switching occurs. Through instantaneous button signals and return delay procedures, power supply switching continuity is ensured. The low-voltage system introduces negative sequence voltage judgment, enhancing synchronization grid connection reliability.

From “Manual Patrol” to “Unmanned Duty”: How Intelligent Protection Changes Operation Modes

In traditional power distribution systems, operators need 24-hour shift patrols, using multimeters and thermometers to check equipment status. This is both time-consuming and prone to hidden risks. With the AM series devices, this Middle East natural gas recycling station achieves a “leapfrog upgrade”:

- Real-Time Monitoring + Automatic Recording: The device collects current, voltage, power, and other data in real-time, automatically recording fault types and occurrence times. Operators can grasp the overall situation in the control room without running around on-site.

- Automatic Fault Handling: Most faults require no manual intervention; the device triggers protection automatically. For example, if a motor is overloaded, it directly cuts off the power supply. During power switching, self-input devices operate automatically, reacting faster than humans by over 10 times.

- Reduced Labor Costs: Through these intelligent functions, the recycling station achieves “unmanned operation.” Operators only need to regularly check backend data, reducing on-site duty demands.

Final Note: Intelligent Protection, the “Invisible Foundation Stone” of Energy Security

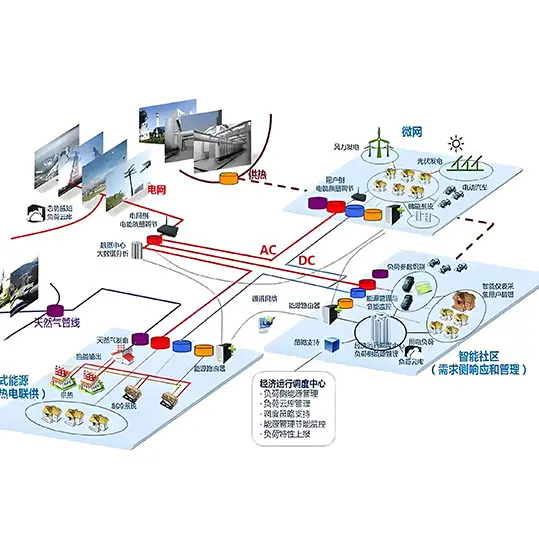

The stable operation of natural gas recycling stations relies on these “power bodyguards” hidden in switch cabinets. The application of AM series microcomputer protection devices not only elevates the reliability level of power distribution systems but also embodies the core logic of the “intelligent grid”—using technology to replace humans, driving decisions with data.

From the Middle East to natural gas stations, such intelligent protection devices are becoming “standard equipment” in power systems. They may be unnoticed, yet silently guard every current flow, making energy production safer and more efficient. This is the power of technological innovation in details.