When Energy Storage Systems Must Include a DC/DC Converter

In energy storage design, a DC/DC converter is not optional.

It determines whether the system can achieve engineering goals.

Many misunderstand DC/DC in two ways:

Misconception 1:

“DC/DC is an optional module that only increases cost.”

Misconception 2:

“High-performance PCS makes DC/DC unimportant.”

Real-world engineering shows DC/DC decides whether the system runs safely, efficiently, and stably under complex conditions.

I. The True Value of DC/DC in Energy Paths

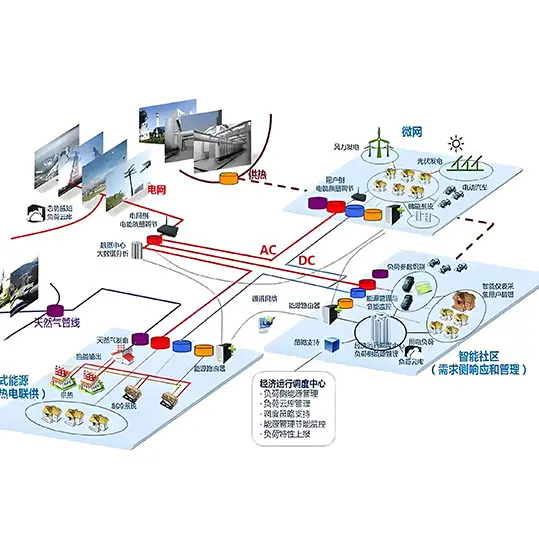

A standard energy storage system energy path looks like:

-

Battery → PCS → Grid/Load (AC side)

Some architectures add DC/DC:

-

Battery → DC/DC → PCS → Grid/Load

In hybrid systems, such as PV-storage integration, multiple voltage levels, or DC load connections, PCS alone cannot handle voltage matching and control simultaneously.

Without DC/DC:

-

Battery voltage may not match PCS DC bus

-

System response slows: PCS cannot manage voltage and dynamics together

-

Stability suffers: SOC changes may trigger protection

With DC/DC:

-

Battery voltage range adapts efficiently

-

Soft isolation between battery and PCS is possible

-

Energy flow optimizes across operating conditions

This enables high-efficiency charge/discharge, reduces battery wear, and improves system stability.

Imax Power often uses DC/DC in energy storage solutions to solve these engineering challenges.

👉 https://www.imaxpwr.com/html/cpzx/

II. Operating Conditions That Require DC/DC

In the following scenarios, DC/DC is essential, not optional:

-

Wide Voltage Range Design

Modern battery packs often use high-voltage architectures to reduce current losses and improve efficiency.

PCS input voltage is limited. Without DC/DC, full SOC coverage is difficult. -

Multi-Source Integration

Examples include:

-

PV + Storage

-

Multiple battery clusters with differing voltages

-

DC load connections

DC/DC provides a controllable, unified DC bus.

PCS can focus on energy exchange, not voltage adaptation.

-

System-Level Reliability Improvement

High-reliability scenarios benefit from DC/DC isolation.

It prevents battery-side issues from affecting PCS or control systems.

III. Engineers Evaluate “System Capability,” Not Module Quality

Many ask, “Which DC/DC is better?”

The real question: “Which engineering problems does this DC/DC solve in the system?”

Imax Power emphasizes system-level coordination and modular design.

It avoids concentrating all functions in a single device.

👉 https://www.imaxpwr.com/html/cpzx/

IV. Conclusion: When DC/DC Is Mandatory

Engineers should prioritize DC/DC in these situations:

✅ Wide voltage range design

✅ Multi-source integration (PV-storage, multiple battery clusters)

✅ High reliability requirements

✅ Strict current dynamic response needs

✅ Soft isolation between battery and PCS

Skipping DC/DC in these scenarios often compromises performance, lifetime, and reliability.

V. Questions for Engineering Decision-Makers

When designing a storage system, consider:

-

Does the PCS handle too many responsibilities alone?

-

Does the battery voltage cover the PCS optimal range?

-

Could multi-source integration disrupt energy flow?

-

Can DC/DC simplify operation and maintenance?

Engineering judgment is about creating a controllable, stable, and scalable energy system, not just stacking equipment.

This article is compiled by the Imax Power Energy Storage Engineering Team based on real projects.

For more energy storage products, power products, and system solutions, please visit:

👉 https://www.imaxpwr.com/html/cpzx/