Different Application Scenarios, Distinct Design Priorities for Energy Storage Systems

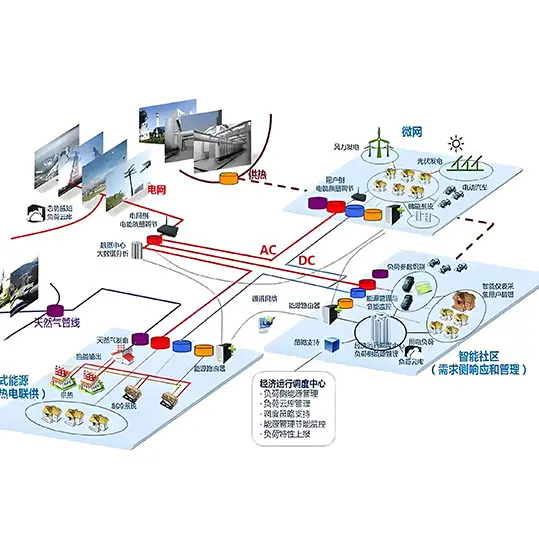

There is no “one-size-fits-all” optimal energy storage solution. Design priorities vary significantly across different application scenarios, a critical fact often overlooked in engineering practice.

I. Peak Shaving & Valley Filling vs. Backup Power: Fundamentally Different Logics

Peak Shaving & Valley Filling:

-

Efficiency is Key: Maximizing energy throughput.

-

Emphasize Cycle Life: Designed for frequent, deep cycles.

-

Slower Response is Acceptable: Grid-scale applications.

Backup Power / Emergency Power:

-

Reliability is Paramount: Ensuring uninterrupted power.

-

Focus on Instantaneous Response: Critical for immediate power restoration.

-

Cycle Count is Lower: Infrequent use, but critical when needed.

Applying a single system logic across all scenarios introduces significant risk.

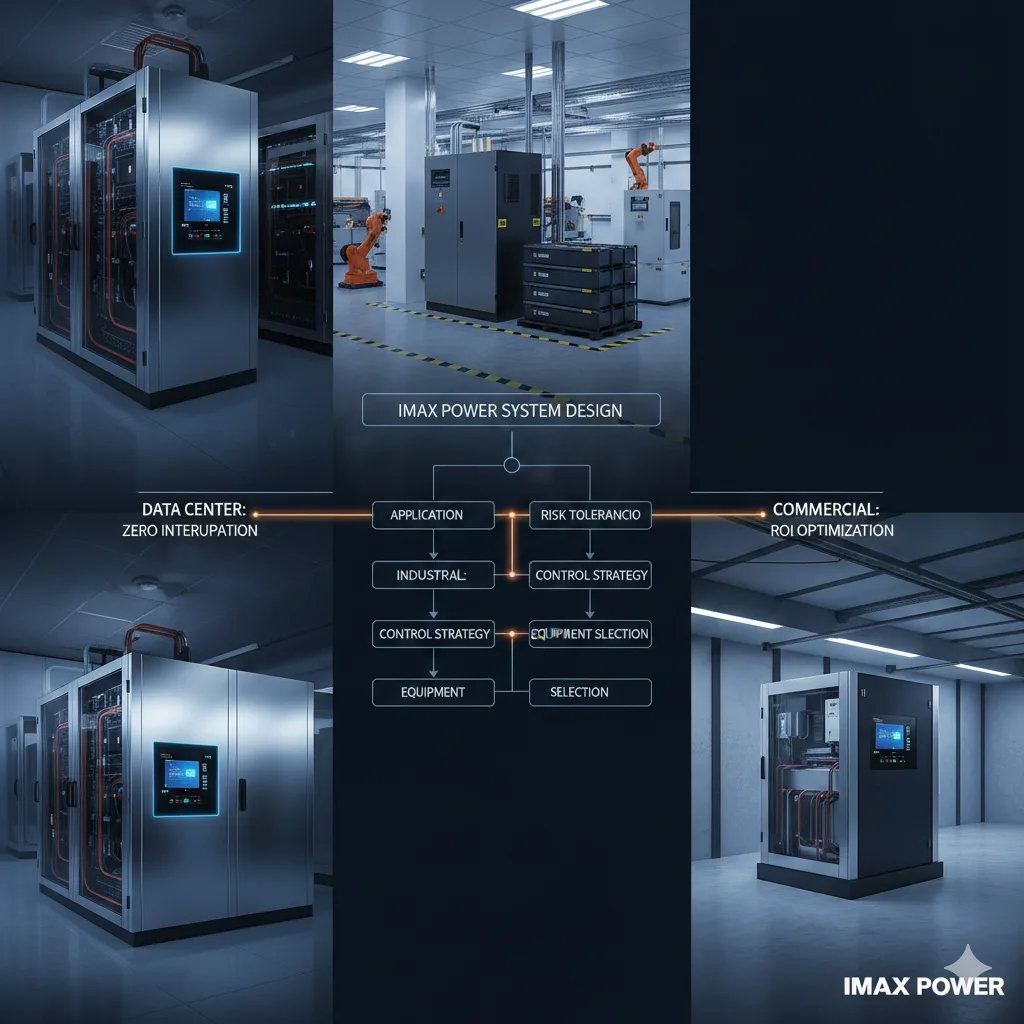

II. Core Differences: Data Centers, Factories, Commercial Buildings

Data Centers:

-

Zero Interruption is Priority: Absolute power continuity.

-

Strict Redundancy & Protection: Uncompromising safety protocols.

Industrial Users:

-

Stable Power & Power Quality: Critical for manufacturing processes.

-

Harmonic Mitigation is Crucial: Protecting sensitive machinery.

Commercial Buildings:

-

Cost & ROI Sensitive: Economic viability drives decisions.

-

Demand Charge Reduction: Key financial incentive.

Imax Power’s system solution designs always start by defining the application scenario. We then reverse-engineer the architecture. We never do it the other way around.

👉 https://www.imaxpwr.com/html/cpzx/

III. Engineer’s Judgment Sequence

A mature engineering judgment sequence should be:

Application Scenario → Risk Tolerance → Control Strategy → Equipment Selection

IV. Conclusion

Discussing energy storage system design without considering the specific scenario inherently creates engineering risk.

👉 Relevant Imax Power Energy Storage & Power Products: 👉 https://www.imaxpwr.com/html/cpzx/