Conclusion First

The choice between domestic and imported energy storage equipment should not be based solely on simple labels. Instead, it should be evaluated from the perspectives of overall system engineering capabilities, after-sales service, performance stability, reliability verification, and regulatory compliance to determine the equipment’s value.

I. Engineering Consideration Dimensions

1) Long-term Operational Reliability

- Has the equipment undergone long-term validation under real-world operating conditions?

- How does it perform in high-temperature, frequent cycling, and high-rate scenarios?

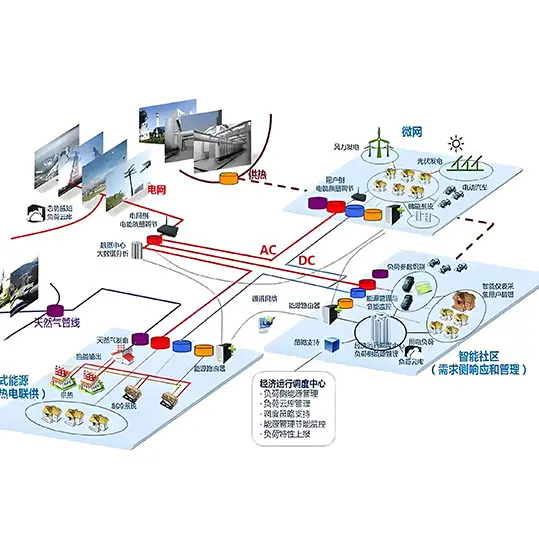

2) System Integration and Compatibility

- Coordination capabilities among PCS, BMS, and EMS

- Standardization of communication protocols

- Adaptability to existing power grids/loads

3) Service and Support Assurance

- Maturity of the spare parts supply chain

- Response time for on-site support

- Remote monitoring and early warning capabilities

II. Engineering Advantages and Disadvantages Comparison between Domestic and Imported Equipment

| Evaluation Factors | Domestic Equipment | Imported Equipment |

|---|---|---|

| Localized Service | Strong | Weak |

| Maintenance Response | Fast | Relatively slow |

| Reliability Verification | Depends on specific product engineering cases | Generally strong standardized verification |

| Cost | Significant cost advantages | Higher procurement costs |

| Compatibility Adaptation | Rapid iteration with the market | Strong long-term stability |

The core selection logic for engineers is to choose equipment that can meet the actual on-site operating conditions and long-term operational reliability, rather than relying solely on the domestic/imported labels.

III. Engineer Recommendation Logic

Prioritize evaluating the following dimensions:

- Availability of long-term on-site validation data

- Support for open standard protocols and modular design

- Maturity of the coordination strategy between PCS and BMS

- Availability of complete maintenance tools and early warning systems

An excellent solution can significantly enhance system stability and long-term returns.

IV. Engineering Solution Examples

1) Large-scale Industrial Energy Storage Project

Project Background: A large manufacturing plant required a 10MWh energy storage system to manage peak demand and improve energy efficiency.

Selection Process:

- Domestic Option: A domestic manufacturer offered a solution with modular design, open communication protocols, and a strong local service network. The equipment had undergone extensive testing in similar industrial environments, demonstrating reliable performance under high-temperature and frequent cycling conditions.

- Imported Option: An imported manufacturer provided a standardized solution with strong reliability verification but higher procurement costs and longer lead times for spare parts. The communication protocols were proprietary, potentially limiting future integration with other systems.

Decision: The plant chose the domestic solution due to its cost-effectiveness, strong local support, and proven reliability in similar industrial settings. The modular design also allowed for easy future expansion.

2) Commercial Building Microgrid Project

Project Background: A commercial building complex aimed to implement a microgrid with energy storage to enhance energy independence and reduce electricity costs.

Selection Process:

- Domestic Option: A domestic provider offered a solution with integrated PCS, BMS, and EMS, supporting open standard protocols for seamless integration with existing building management systems. The equipment had a proven track record in commercial applications and offered rapid on-site support.

- Imported Option: An imported solution provided high-performance components but required custom integration efforts due to proprietary protocols. The cost was significantly higher, and the maintenance response time was longer due to the need for international shipping of spare parts.

Decision: The building complex selected the domestic solution for its cost-effectiveness, ease of integration, and strong local service capabilities. The open standard protocols ensured future compatibility with other smart building technologies.

V. Conclusion

The choice between domestic and imported energy storage equipment is not a one-size-fits-all decision. Engineering value should be the core criterion. The final selection should be based on the principles of optimal reliability, compatibility, service capabilities, and lifecycle costs.

For reference to engineering solutions that prioritize engineering value, visit Imax Power’s website at https://imax-pwr.com/product/ and explore our range of energy storage products designed to meet your specific needs while ensuring long-term reliability and cost-effectiveness.